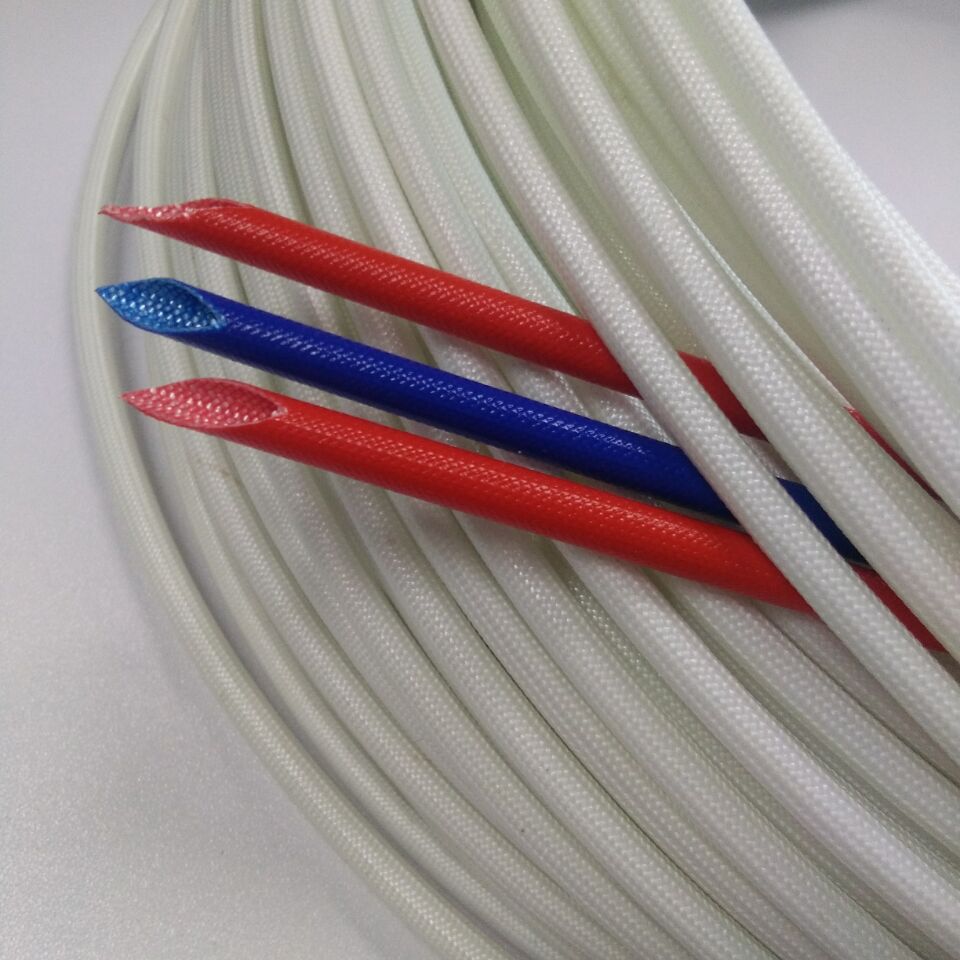

It is woven as sleeving by non-alkali fiberglass and coated with rubber in high temperature. It has better dielectricity, automatic quench and softness than silicone fiberglass sleeve, widely used in the insulation protection of internal line clusteri in H&N machinery, household electrical appliances, electroheat and special illuminations.

1. Normally inside diameter: 0.5mm~25.0mm

2. Maximum working temperature: 200oC

3. Breakdown voltage: 4.0kv, 7.0kv

4. Resistance to flame: VW-1

5. Good flexibility, arc resistance,self extinguishing, non corrosive, fungas resistant

6. Standard color: white (Black, Red, Yellow, Blue...other colors upon request)

|

Silicone Rubber Fiberglass sleeve |

||||||

|

Technical index: Volume resistance: 10'' Ωcm, Automatic quench time: 10S |

||||||

|

Type/File No. |

Testing condition |

Flammability |

Operating Temperature |

Breakdown voltage grade |

Average voltage |

Individual |

|

FGS-1 E232837 |

UL1441 |

UL VW-1 |

+200℃ -10℃ |

B |

4000V |

3000V |

|

FGS-1U E241093 |

UL1441 |

UL VW-1 |

+200℃ -10℃ |

A |

7000V |

5000V |

|

|

||||||

|

ITEM |

VALUE |

|||||

|

Continuous Operating Temperature |

-60℃ +200℃ |

|||||

|

Temperature Endurance |

200℃±2℃ 168hr≧1/2 former voltage value |

|||||

|

Aging Test |

260℃,6hr,NO cracking |

|||||

|

Cold Bend |

NO cracking |

|||||

|

Horizontal Flame Test |

<30seconds |

|||||

|

Flame Retardance(VW-1) |

<30seconds |

|||||

|

Volume Resistivity |

10''Ω.cm |

|||||

|

Submerge Water Test |

Not gum, not distortion and emolliated |

|||||

|

Inside diameter |

||||||

|

Inside diameter |

Wall thickness |

|||||

|

Normal |

Tolerance |

4000V |

7000V |

|||

|

0.5-2.0mm |

+0.20±0.00mm |

0.40±0.05mm |

0.50±0.05mm |

|||

|

2.5-3.0mm |

+0.25±0.00mm |

0.40±0.05mm |

0.50±0.05mm |

|||

|

3.5-5.0mm |

+0.35±0.00mm |

0.45±0.05mm |

0.55±0.05mm |

|||

|

6.0-9.0mm |

+0.50±0.00mm |

0.50±0.05mm |

0.60±0.05mm |

|||

|

10.0-12.0mm |

+0.70±0.00mm |

0.60±0.05mm |

0.65±0.05mm |

|||